Africa to become a leader in Industry 4.0.

Africa to become a leader in Industry 4.0?

Do you want to manage Industry 4.0 between latin America and Africa?

Contact us here, mayado@sylodium.com for be our blogger managing the niche you choose: Tanzania – Argentina, Nigeria – Mexico, Africa – Brazil, Caribbean – Africa in Industry 4.0

We are in Industry 4.0 (3D printing, AI, Big Data..) between Latin America and Africa,

if you are a good thinker, visionary, hard studious, you can become our blogger in the niche you choose so we (you and us) will win money together.

Tap our unique Crossing System.

New from CAJNewsAfrica.com

Time for Africa to leapfrog into 4th industrial revolution

By Amr Kamel,(CAJ News)

AFRICA must develop its value-added manufacturing sector. From government to the private sector and academia, it’s agreed that this is the way for the continent to grow and continue to support a rising population and growing middle class.However, it has a way to go. In 2014, 30 percent of China’s GDP came from manufacturing,according to the World Bank.Comparatively, Nigeria’s was just 9 percent, Kenya 12 percent, and Zambia 8 percent.Africa is also at a crossroads. With a global focus on mitigating the effects of climate change and drastically reducing our carbon footprint, the world is on a mission to make the manufacturing industry cleaner, greener and more sustainable. But where does this leave rapidly developing economies?

Africa poised for growth through green industrialisation.

From using steam to mechanise production in the first industrial revolution, to the harnessing of electric power in the second, manufacturing has traditionally been energy intensive.

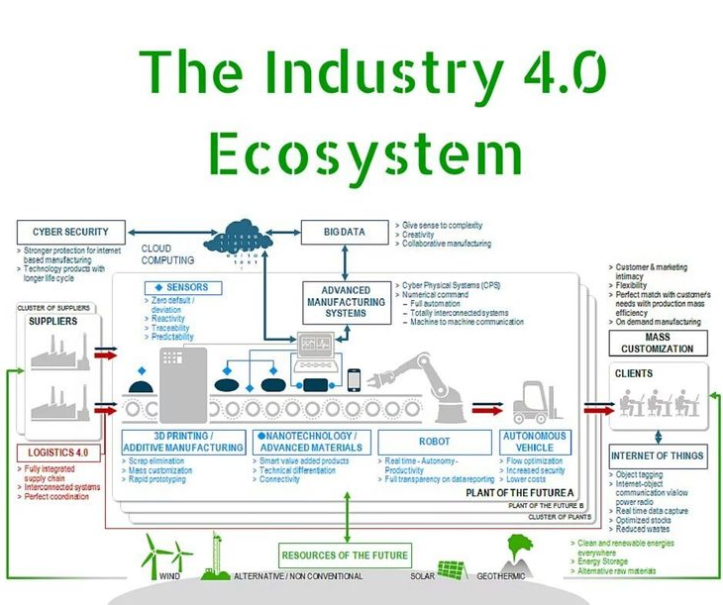

With the development of information technology in the third industrial revolution, and now with big data, the Internet of Things (IoT) and artificial intelligence (AI) ushering in Industry 4.0, Africa is at the cusp of a revolution that has tremendous opportunity for the continent.Traditionally, the heavy reliance on energy resources, infrastructural gaps and a skills and productivity shortage, has undermined the global competitiveness of Africa`s industrial sector.However, by leapfrogging to Industry 4.0, Africa can take advantage of greener, more productive technologies without being encumbered by outdated, energy and labour intensive processes.

By leapfrogging, Africa will be closer to achieving sustainable and inclusive growth, and meaningful employment while safeguarding its natural assets.Using big data to grow Africa’s manufacturing industry. Most manufacturers generate a huge amount of information, from the sourcing of materials to the marketing and distribution chain.

Each of these functions has countless moving parts, both on the production line and off. Understanding and utilising all this data efficiently has become paramount in today’s age of information.

How Industry 4.0 can revolutionise manufacturing.

For most manufacturers, energy is the first or second highest cost (after labour). By using data, companies can make demand-driven decisions, for example running equipment in conjunction with fluctuations in consumer demand, to save energy.Extending use cycles: Intelligence provided by IoT and big data provides predictive maintenance, which can keep equipment functioning optimally. By keeping machines in use for a longer period it reduces the need for new ones to be manufactured – lowering impact on the environment and saving costs.

Increasing efficiency: In addition to reducing downtime, new technologies make factories more efficient and save power. Data can also track labour output, for example managing shifts optimally to increase productivity.Reducing waste and emissions– Technologies like IoT reduce greenhouse gas emissions in the supply chain by tracking and managing energy use.

Workforce optimisation: Companies can use data to balance workforce requirements. Reduced overtime expense can be a major source of savings.

Product inventory: Keeping product inventory for a long period of time comes at a cost. Manufacturers need to consider the cost of storage, any necessary insurance, maintenance and other factors.

Whenever possible, manufacturers will benefit from nimble and responsive manufacturing operations to avoid overproduction.

Product supply chains: Smart manufacturing will shift supply chains. There is a so-called “makers movement”, where companies are choosing local suppliers, connecting them with demand both close and far from home. It promises a more efficient form of production, and more sustainable processes where resources are re-used. For example, where bio-waste is used for feed stock or fed back into the production process. This leads to a circular economy, which brings the efficiency that is at the heart of smart manufacturing.

Turning Africa’s challenges into opportunities

The path towards green industrialisation on the continent can only be paved by the adoption of a combination of investment in innovative technologies, skills training, and the willingness to implement policies that identify green industrialisation as the backbone of the continent’s socioeconomic transformation.Africa has proven its capacity to leapfrog. The world’s most ground-breaking mobile innovations come from the continent because of this ability. With bold leadership, we can do it again, and become a leader in Industry 4.0.